-40%

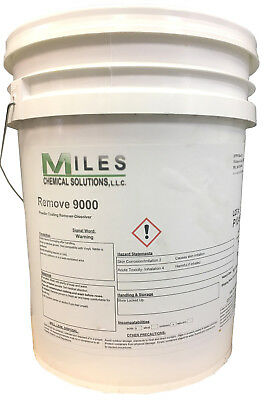

Remove 9000 Powder Coat Remover to "remove powder coating at room temperature"!

$ 221.99

- Description

- Size Guide

Description

5-Gallon Pail Reusable Liquid Powder Coat Dissolver"Remove" Powder Coat Remover | Remove Powder Coating from Hooks, Racks & Powder Coat Rework at

Room Temperature

. Remove 9000 is Eco-friendly, Non-regulated by US DOT, Operator friendly, Non-Caustic, Non-Acid and Low Odor & won't burn your skin in case of accidental contact. Powder Coating Remover.

Reusable:

Keep in mind that strip time is predicated on cured powder coat film build and Type of powder being removed, i.e., TGIC and Polyester Powder Coat 3 mils thick can be removed in 15-25 minutes, while 3 mils of cured Epoxy Powder requires 1.5-2 hours to dissolve. After purchasing a 1-Gallon or 5- gallon container to evaluate, we recommend that you immediately remove or set aside 20-30% portion of the virgin REMOVE 9000 to keep in a covered container for use as virgin replenishment, once you have stripped enough hooks & parts to decant and remove the sludge in your working solution container. Replenishment with virgin REMOVE 9000 Dissolver product keeps the solution performing for you up to 12-14 months with proper sludge removal and replenishment.

Disposal:

If you strip only non-hazardous powder coating in the REMOVE solution, you may dispose of the solution per your local regulations as a non-hazardous liquid. Our customers have utilized a non-hazardous Floor-Dry media or Floor absorbent pads or socks to dry the non-hazardous sludge to dispose of as a solid.

Description: Remove 9000 Room Temperature Powder Coat Remover

is a Non-Hazardous, Ready-to-Use Powder Stripper that removes All Types of Powder Coatings including: TGIC, Polyester Powder Coatings, Epoxy Powder, Varnishes & Adhesives. Operator Friendly, No-Methylene Chloride Formula.

Directions:

Remove 9000 will remove Powder Coat in 15 minutes to 1-2 hours at

Room Temperature (70F.) in an

immersion

tank, drum or pail. It's Aluminum

& All Metal Safe. Formulated to Clean Powder Coating from Hooks,

Racks and Coating Rework at Room Temperature. Strip time will vary

depending on type of coating and coating film build. Mechanical

Agitation is not required, however will accelerate stripping.

Keep container closed and a lid on your process tank at all times

. Air agitation

is not recommended: Air-(Oxygen will reduce solution life). Use No-

Water with Remove 9000. Rinse parts with water after stripping.

Contact Seller for Material Safety Data Sheet: MilesChemicalSolutions

Visit site for further information:

RemovePowderCoatPaint